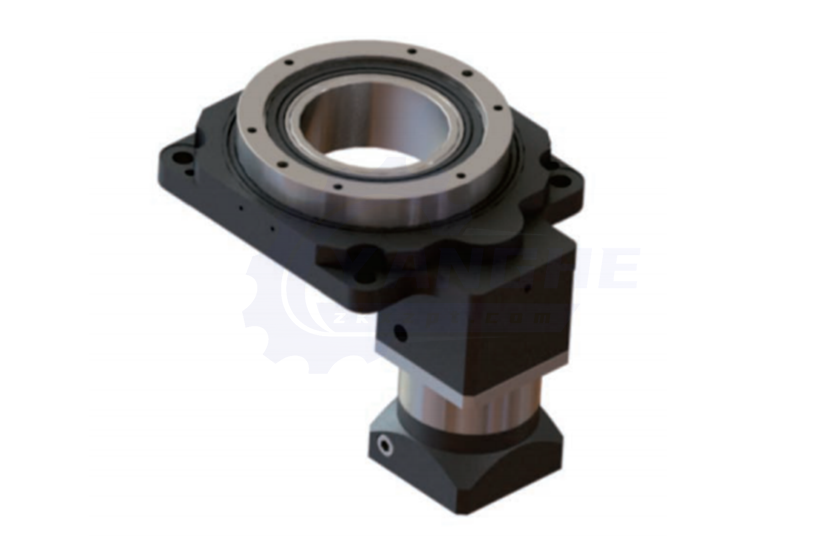

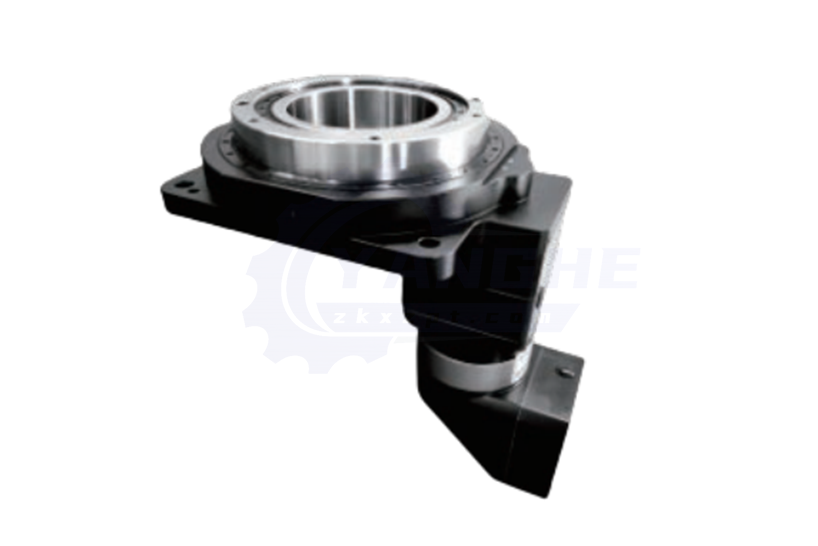

- Category:YHN130 Size

- Direct connection can improve reliability and reduce costs The workbench and robotic arm that need to be installed can be directly mounted on the rotating platform. Compared with using mechanical parts such as pulleys, it can reduce the time and cost of mechanical design, part allocation, and belt state adjustment. Motor configuration You can freely choose from various brands of stepper motors or servo motors. High precision positioning without backlash No backlash, positioning accuracy ≤ 1min, repeated positioning accuracy up to ± 5 arc seconds Large caliber hollow structure Wiring and piping are more convenient and concise, and this characteristic is particularly prominent in complex wiring and piping environments.

YHN130-10K/18K

Do you want to know more?